Understanding Material Blockage: Types of blockage and how to restore material flow

Material blockage can quickly become a hazardous and costly problem if ignored. Blockage in any form presents problems that should be addressed as soon as possible. It is important to understand the different types of blockage that can occur.

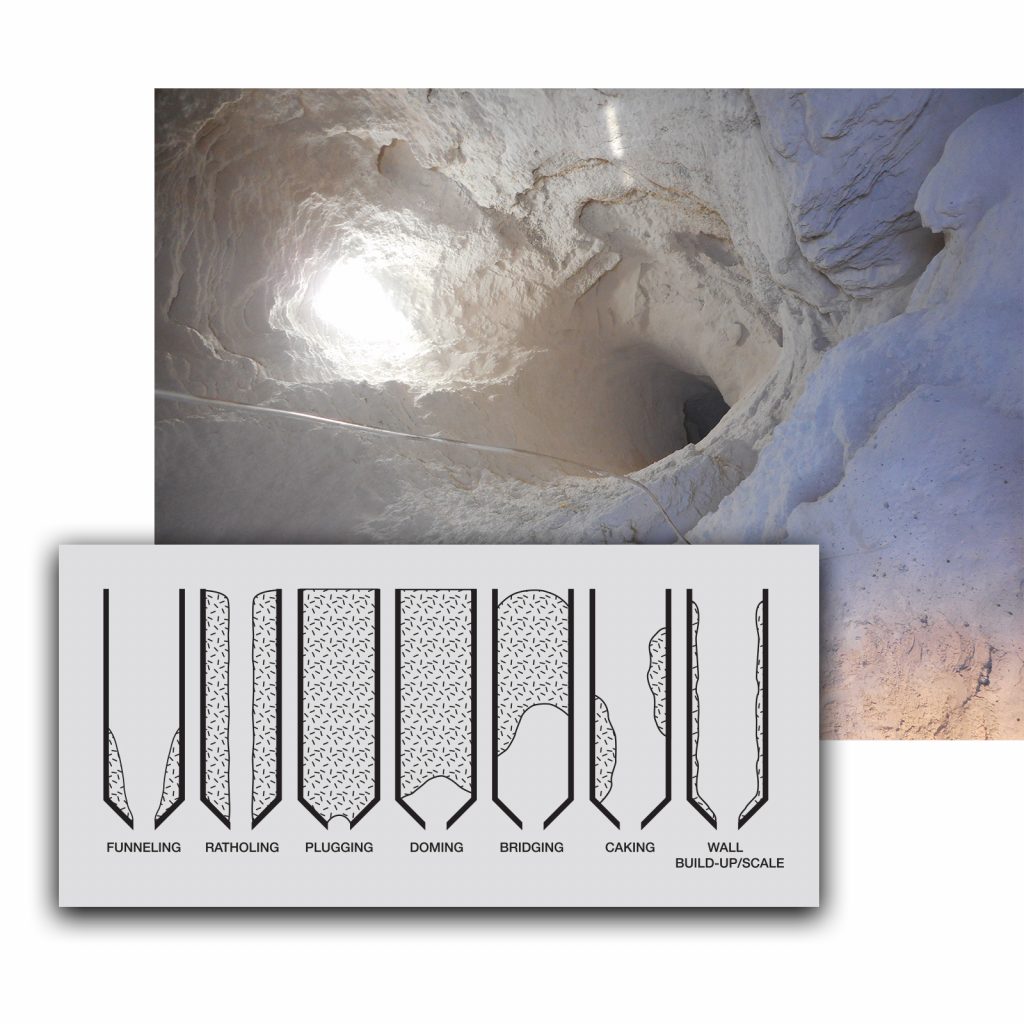

Types of Silo Blockage

Blockages are generally organized into three primary categories: Ratholing, Bridging, and Caking

Ratholing

Ratholing occurs when material clings to the sides of a silo, leaving only a small hole from which the material can escape. This small funnel often leads to further blockage as the material is unable to flow freely and the buildup on the sides increases.

Ratholing is sometimes the result of asymmetric flow and can put undue pressure on silo walls. The integrity of the silo’s construction can be put at risk as a result.

Bridging

Bridging occurs when material sticks together forming an arch-shaped blockage (resembling a bridge) over a silo discharge. Bridging results in a complete flow obstruction and can place extreme pressure on the silo walls.

Doming is similar to bridging in that an arch is formed above the discharge and all material on top is blocked from escaping.

Caking

Clumps often form when material becomes stagnant or moist. This caked material impedes the natural flow, causing plugging and asymmetrical flow dangers.

Caking can occur at any place within a silo but can cause flow disruption regardless of location.

Blockages can result from a number of complications:

- Improper silo design

- The wrong material in the wrong silo structure

- Moisture within the material

- Limited preventative maintenance and structural inspections

How to Handle Silo Blockage

A few of the tools in our arsenal are described below:

The Junior 360º™ Whip System – A DIY equipment option that is portable, flexible and safe. The Junior 360 eliminates the need for human entry, while quickly and efficiently restoring your silo to normal operation. This proprietary system does not risk product contamination and fits most any vessel.

Available for purchase or rental.

Arch•Master™ – The Arch•Master™ is a durable drill system and the ideal unit for many tough blockage jobs, particularly bridging or arching across an entire silo. The powerful features provide maximum versatility and the ability to handle difficult jobs efficiently and safely.

Available for purchase or rental.

Safe-T-Shot™ – Some buildup has become so hardened that a powerful blast is necessary to break up the blockage. Our Safe-T-Shot™ is designed to use high-pressure, inert CO2 gas to directly target difficult areas.

Available for purchase.

Big•Mole™ System – A professional team onsite is often the only option for extremely difficult jobs. Mole•Master’s Big•Mole™ Service provides quick, efficient and safe silo cleanout, minimizing downtime and maximizing productivity. Our Big•Mole™ System requires no human entry, introduces no contamination, recovers material and storage capacity completely and does not require liquids or sparking.

Professional crew available for hire.

Please fill out our Service Quote Request or Equipment Quote Request to receive a customized quote for your silo cleaning needs. You may also call 1.800.322.6653 (U.S.A. only) or 740.374.6726 to speak with a technician ready to help solve your problem.