Structural Silo Inspection

Silo Inspection Can Save Money…And Lives

Many silos in use today date back to the 1940s. This may not seem like a problem because silos appear to be indestructible from the outside. The fact is many silos across the country have never been inspected structurally or otherwise. These storage vessels can degrade due to weather, usage, and simply the passage of time. Without an inspection to uncover any integrity issues, silos can actually collapse without warning. Not only is this a problem in terms of replacement cost; worse yet, it can cost the lives of anyone working on or around the structure. Since the 1980s, Mole•Master™ Services Corporation has offered professional silo inspection services to help prevent these types of disasters.

There is no reason for this type of accident to occur. Properly certified, experienced structural engineers familiar with the pressures seen by silo walls during the process of filling, storing and discharging, can evaluate a silo to make sure everything is structurally sound. An investment now can truly prevent future tragedies.

What to Expect during a Mole•Master Inspection

Mole•Master™ approaches all projects with safety and clear communication as the top priorities. Silo inspection projects are certainly no different in that regard. Part of this communication is working with the customer to develop a plan, prior to the start of the project, that clearly provides a scope of work and meets the customers’ expectations. Depending on how the silo empties prior to the inspection, a thorough cleaning might be required.

The Mole•Master™ Silo Inspection process includes the following steps:

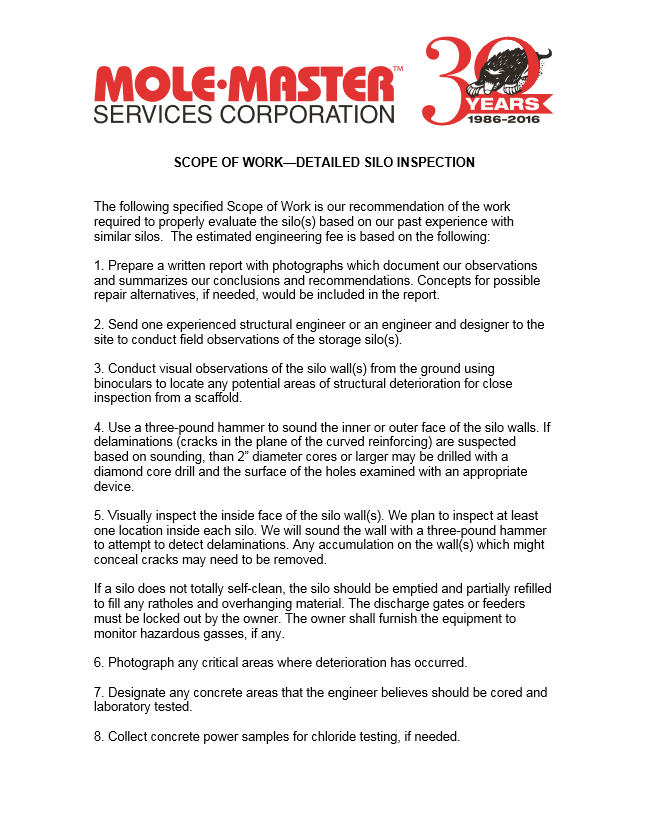

- A structural engineer, sometimes accompanied by a designer, visits the site to conduct field observations.

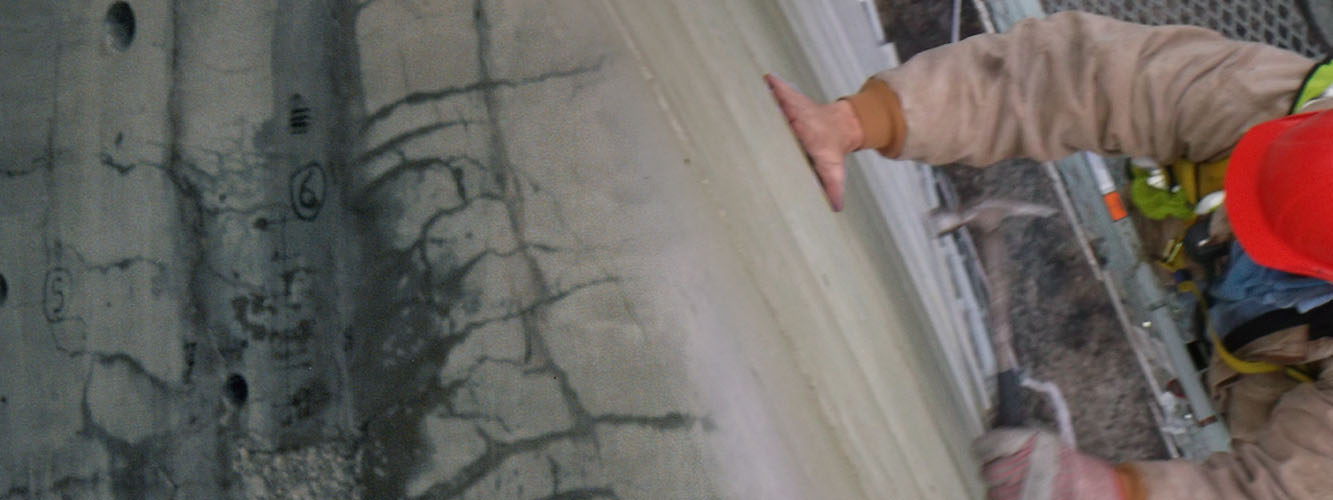

- The engineer visually observes the exterior silo walls using binoculars to see if there are any areas of deterioration that should be looked at more closely. These visual cues include cracking, bulging, or material leakages.

- A three-pound hammer is utilized to test the wall of the silo in multiple locations. This sounding process can help determine if there is a potential for delamination. If issues are suspected, the engineer may drill and remove a small core from the wall for further inspection.

- Visual inspection of the silo’s interior occurs next. If there are areas where build-up has accumulated, the engineer may request it be removed so the walls can be evaluated more effectively. Mole•Master’s exclusive, proprietary Big•Mole™ Service, the Junior 360º™ and the Arch•Master™ Portable Auger system can be used for these purposes.

- Any areas of deterioration are photographed.

- After the inspection, Mole•Master™ will detail any areas that should be cored and tested.

- After the work is completed, a written report is submitted to the customer. This will summarize all observations along with recommendations on how to fix any problem areas.

Structural silo inspections are appropriate for silos in all industries, including feed and grain, cement and coal.

If you’re interested in learning even more, click here to read our favorite silo inspection tips.

Mole•Master utilizes proprietary equipment to ensure safety and efficiency during every silo inspection.